-40%

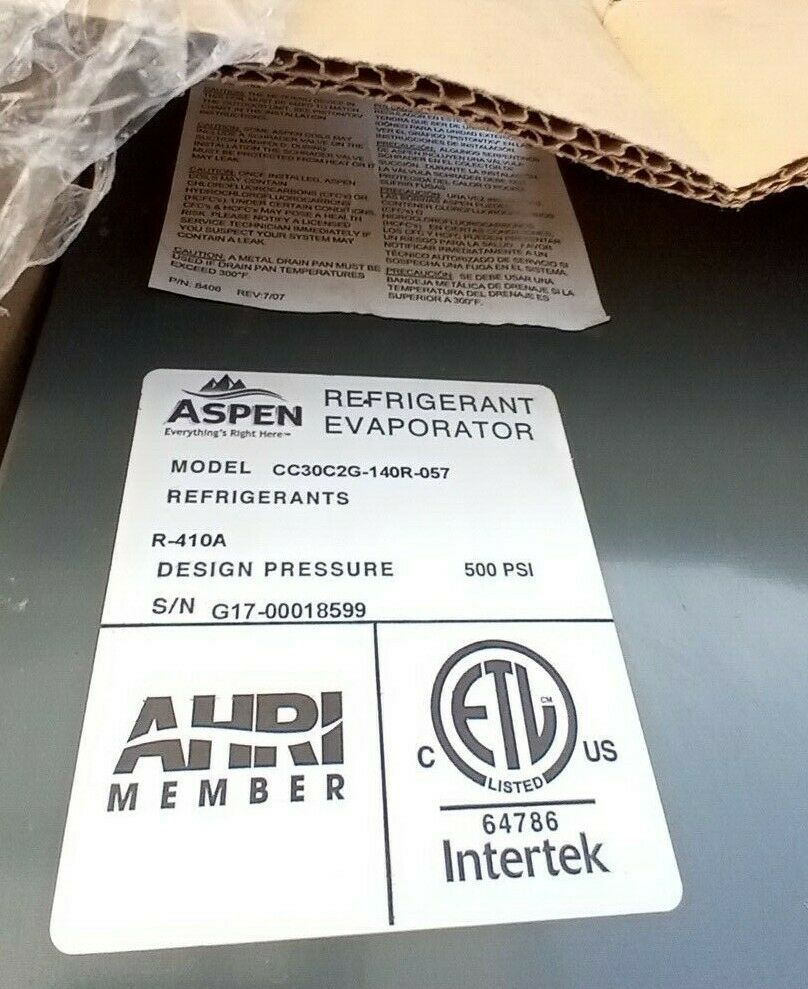

ASPEN EVAPORATOR COIL MODEL # CC30C2G-140R-057 R410a 500 PSI

$ 183.52

- Description

- Size Guide

Description

Please see photos, email any questions.Cased Upflow/Downflow Evaporator Coil - CC Series Goodman Matches - Gray Paint

Nom. Tons: 2-1/2; Liquid Conn.: 3/8"; Suction Fitting: 7/8"; Width: 14"; Height: 20"; Depth: 21-1/2"; Wt. Lbs.: 44; Description: Cased; Configuration: Upflow / Downflow; Metering Device: TXV; Color: Gray; Coil Type: Cased; TXV Included: No;

Order #:

B79-522

Mfg. #:

CC30C2G-140R-057

Brand:

Aspen Manufacturing

The Aspen CB Horizontal Evaporator Coils

are compatible for use with Goodman Gas Furnaces, Split System Air Conditioners and Heat Pumps, as well as modular, two-piece blowers. Each cased coil has a quality, galvanized-steel cabinet.

Standard Features:

Rifled copper tubing, enhanced aluminum fins.

Immersion-tested at 500 psi, then nitrogen-pressurized and sealed.

Liquid line - 3/8” ODS, suction line - 3/4” ODS on 1-1/2- 3 ton & 7/8” ODS on 3-1/2 - 5 ton.

Inlet and outlet dimensions are identical (without end caps).

Externally mounted flowrater body with Schrader valve for hiss-testing.

Refrigerant lines exit from the top of the coil.

Split access doors on top of the coil for easy service.

Embossed galvanized cabinets standard.

Top, bottom, and side flanges for furnace connection

Fully insulated cabinets with faced insulation.

Heavy duty plastic drain pan with four 3/4” FPT galvanized condensate drains (two per side).

Pan is positively sloped toward drains.

AHRI certifiable with all brands of A/C and heat pump systems.

ETL listed for use with R-22 and R-410a when proper metering device is used.

Ten-year limited warranty.

Popular Options:

Factory or field-installable TXV.

Powder painted stainless steel drain pan.

Schrader mounted on suction manifold, external to cabinet.

**IMPORTANT NOTE** SINGLE EVAPORATOR COILS ARE SHIPPED VIA GROUND TRANSIT SERVICES. UPON UNPACKING YOUR EQUIPMENT, YOU MAY FIND THAT SOME OF THE COIL FINS ARE SLIGHTLY BENT. BENT FINS ON YOUR EVAPORATOR OR CONDENSER COIL ARE COMPLETELY NORMAL AND HAPPENS DURING THE MANUFACTURING AND ASSEMBLY PROCESS, NOT DURING TRANSIT. BENT FINS WILL NOT IMPEDE THE FUNCTIONALITY OF YOUR EQUIPMENT AND DOES NOT CONSTITUTE EQUIPMENT "DAMAGE". CLAIMS CANNOT BE FILED FOR BENT FINS. UNLESS THERE IS VISIBLE DAMAGE TO THE EXTERNAL PACKAGING AND/OR PANELS OF THE UNIT, THESE CLAIMS CANNOT BE ACKNOWLEDGED.